Name of invention:

A type of marine urea solution preparation equipment and its preparation method.

The product was authorized the invention patent by the State Intellectual Property Office of the People’s Republic of China on 6th Aug, 24.

Patent number: 202410307628.X

At the end of 24, Marine Urea solution production plant were successfully delivered to Asakawa Shipyard in Imabari, Japan. it was independently developed and manufactured by ContiOcean . The performance of the equipment has reached the international leading level, and the production of urea solution meet the quality characteristics of ISO 18611-1:2014--Marine NOX reduction agent AUS40- aqueous urea solution at 40 % concentration (AUS 40).

According to statistics, in 2008, the pollutant emissions of global maritime vessels accounted for 18%-30% and 9% of the total NOx and SOx emissions. As a result, the International Maritime Organization (IMO) has introduced the most stringent IMO Tier III emissions standards in history, requiring a nearly 76% reduction in NOx emissions from Tier III-compliant engines compared to Tier II standards. Existing technologies that meet IMO NOx Tier III emission limits include: Selective Catalytic Reduction (SCR) system, Exhaust Gas Recirculation (EGR), alternative fuels, etc. SCR technology is one of the more effective methods to reduce NOx emissions, It can effectively remove more than 70-90% of the nitrate.

SCR technology refers to the use of reducing agents (such as NH3, liquid ammonia, urea) to "selectively" react with NOx in flue gas and generate non-toxic and pollution-free N2 and H2O under the action of a catalyst (widely used catalyst is V2O5/TiO2).

Therefore, ships adopt SCR technology must replenish and storage urea solution. But the procurement cost and transportation cost of urea solution are higher than that of urea granules, and the storage time of urea solution is limited, and the manufacturer recommends an expiration date from the date of production: Usually 6 to 18 months (depending on storage temperature).

AUS40 urea solution can be purchased from a limited number of ports, so must be purchased in bulk for storage, but unused residual urea solution is likely to expire, and If the composition test results fail before use after long-term storage, it must be disposed of or forced consumption outside a Level III restricted area. In addition, many ports do not recycle IBC standard urea solution packaging containers, and the cost of abandonment is high.

At present, the urea solution production plant used on ships generally has problems, such as incomplete dissolution of urea granules, feeding trouble, and engine room environmental pollution of by gas overflow during manufacturing.

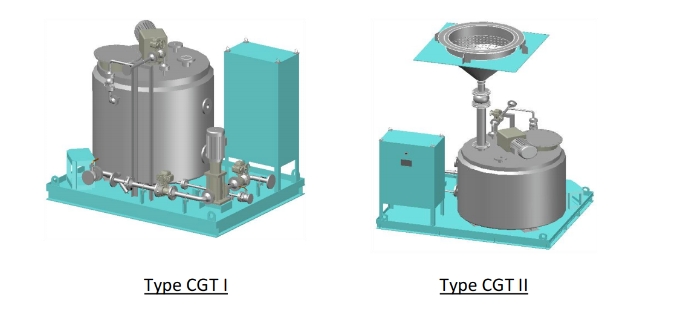

In view of the above problems, ContiOcean independently developed and designed the CGT series urea solution production plant, by adopting the installation and operation suggestions of various parties. Quantitative urea granules are added to the pure water produced by the ship's water generator according to the ratio, and are fully stirred in the mixing tank, while jacketed heating is used to speed up and ensure the complete dissolution of urea granules. At the same time, an exhaust port is added to the tank, and the pipe is led to the open deck as needed, so that the environment of the urea solution production plant site can be regarded as zero pollution. Ensure the safety and high quality of AUS4O production of urea solution.

At present, urea solution production plant of various specifications and models have been highly recognized in domestic and overseas markets, especially in Japan and South Korea, and have achieved good sales performance.

On the basis of the Marine AUS40 urea solution production plant, Contiocean has also successfully developed AUS32 for vehicles, which integrates the form of pure water generator and urea solution quantitative filling device, the urban water input, AUS40/AUS32 output mode, to meet the market demand.